\\ Mirai (未来 or 未來) is a Japanese given name, meaning "the future". //

polywood

In the fall semester of 2020 I was fortunate enough to work as a design intern at POLYWOOD Inc.. POLYWOOD is one of the fastest growing leaders in outdoor furniture with a mission to create sustainable products good for the Earth. Their furniture is made from 100% HDPE with plastics that are ocean or landfill bound, so everything is recyclable.

During my time at POLYWOOD, my goal was to push what could be done at POLYWOOD Inc. and learn what was possible at a company that did their development, design, manufacturing, and engineering in-house at one site.

simplicity

japanese joinery . scandinavian . modern

how can we bring the indoors out?

As the pandemic has surged on through the seasons, the common trend has been to get outside. The great outdoors has become the escape from the work at home routine. So how can we bring some of the comfort of our homes and the places we gather around outside?

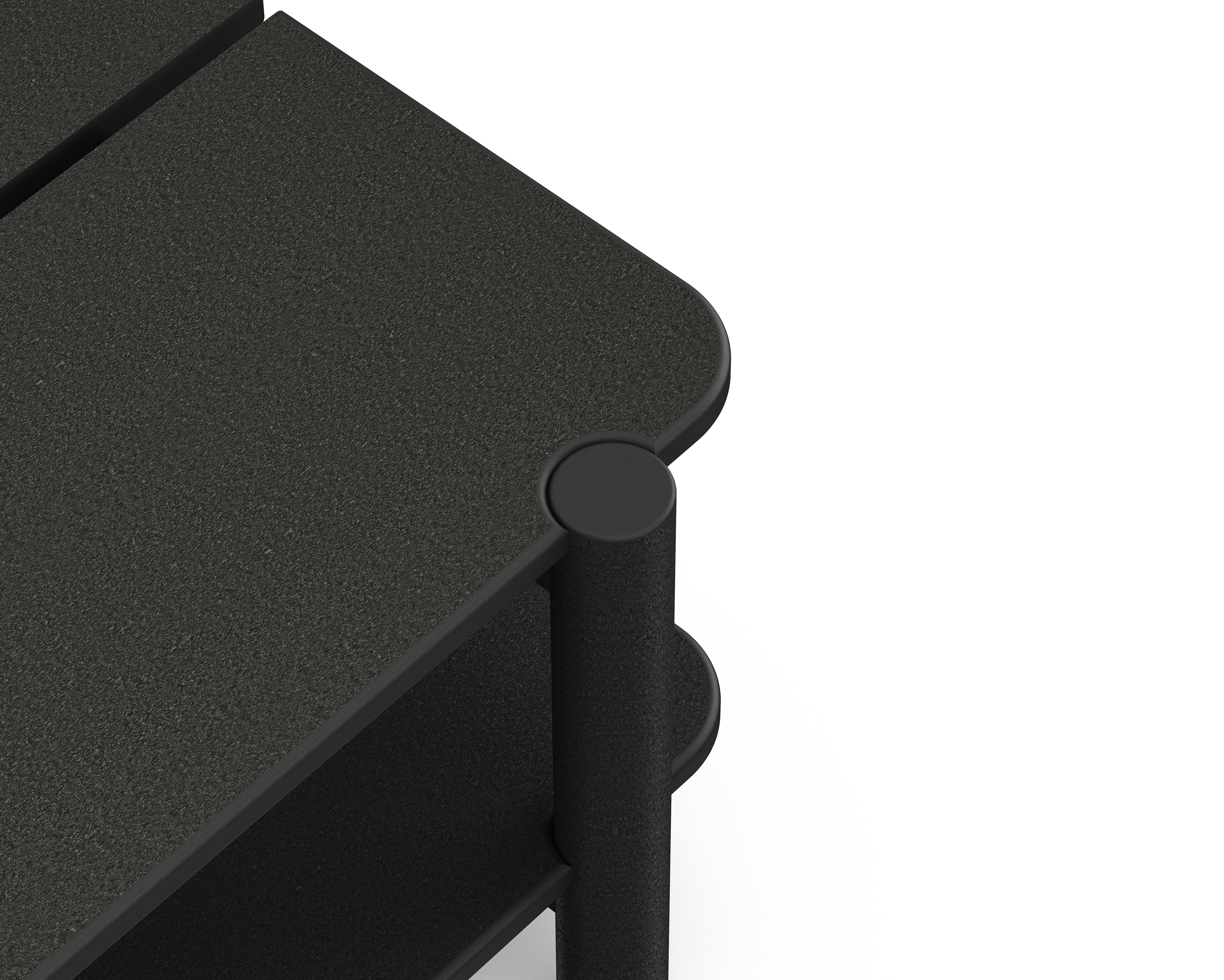

surface interactions

leg connections

I wanted to keep the overall build of the coffee table simple, so I knew the key aspects that would create the feel of the table would be in the details. The legs on a table can be a feature that is hidden, but I wanted to highlight them and showcase that connection throughout the design.

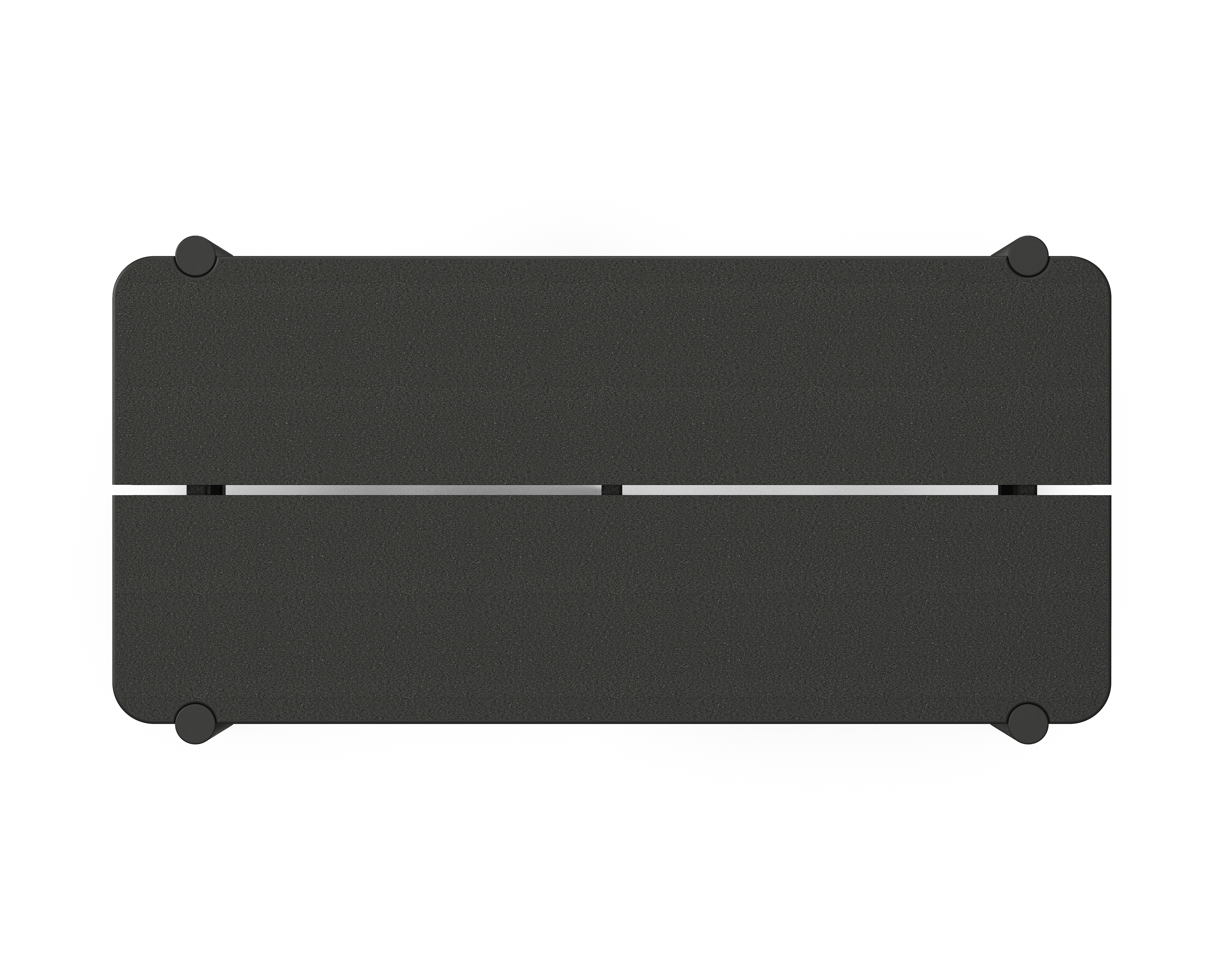

light-weight

One of the characteristics of the POLYWOOD material is its physical weight which can sometimes translate into its visual weight. From the beginning, I wanted to be mindful and create something that didn't feel heavy. I wanted it to feel light.

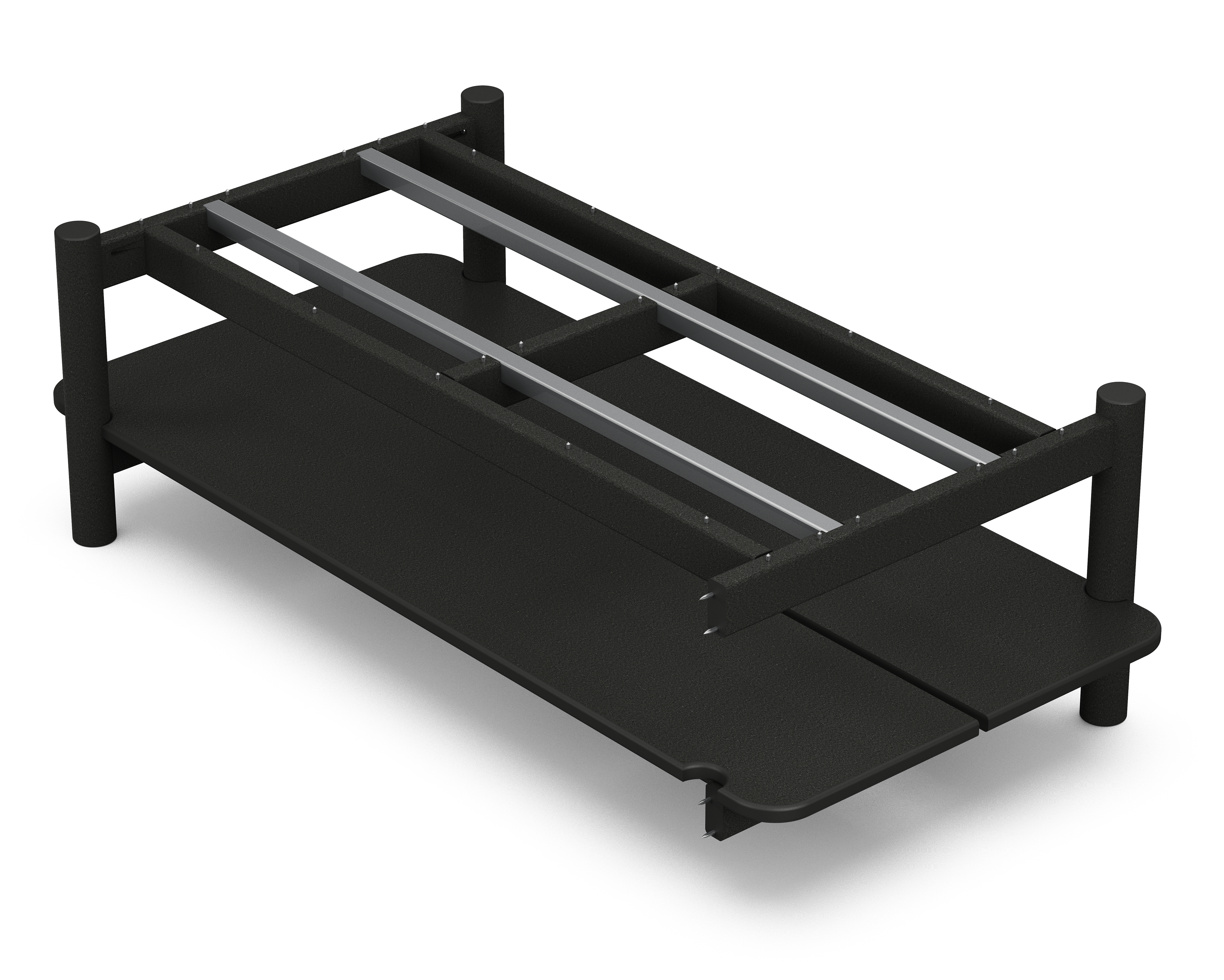

instagram vs reality

The idea for the first prototype was that the lower table could be moved out to create an extension for the coffee table if the space was a larger one. After testing the conversion myself and having several other people do it, I found that the action was difficult due to the weight of the lower table itself as well as the tight fit.

back to the drawing board

The first prototype revealed some structural problems in the design. Since POLYWOOD lumber is able to flex so much, the bracing wasn't able to keep the table stiff and allowed the table to rock. POLYWOOD lumber is also not 100% consistent in terms of tolerances, meaning the spacing of the round posts to the table tops was large enough to move around. I also wanted to make some improvements with the connections on the table that would make it easier to put together in production while making it stronger.

mirai

Duration: 10 weeks

Skills: SolidWorks, Photoshop, Keyshot, Prototyping, CNC Machining.